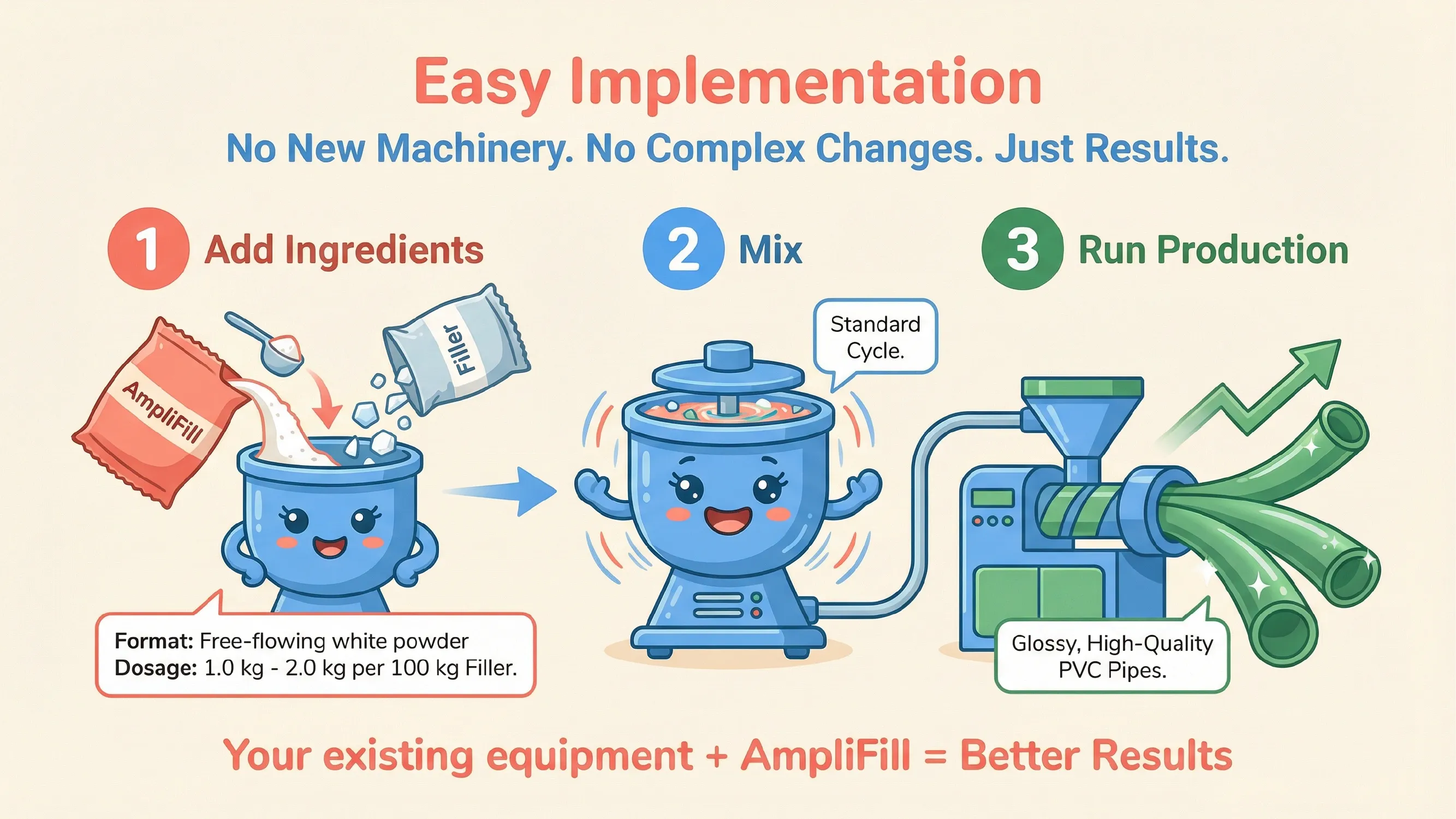

So Easy, It's Almost Unfair

Implementing AmpliFill takes minutes, not days. No new equipment, no process changes, no headaches. Just add, mix, and save.

Three Simple Steps

Start saving money today with this straightforward process.

Calculate Dosage

Calculate your AmpliFill dosage based on your CaCO3 filler percentage in the recipe.

- AmpliFill 150: Total % CaCO3 ÷ 5 = % Dosage

- AmpliFill 300: Total % CaCO3 ÷ 10 = % Dosage

- Example: 30% CaCO3 = 6% AmpliFill 150 or 3% AmpliFill 300

Mix as Usual

Run your high-speed mixer at standard cycle. No special equipment or process changes needed.

- Use your existing high-speed mixer

- Standard mixing time (3-5 minutes)

- No temperature modifications required

Extrude & Save

Run your extruder as normal. Watch the savings roll in with improved output quality.

- No machinery modifications needed

- Same or improved processing temperatures

- Better surface finish, higher throughput

Why It's So Easy

AmpliFill was designed for seamless integration into existing production lines.

Zero Downtime

No production interruption to implement

No New Equipment

Works with your existing machinery

Immediate Results

See savings from the first batch

Better Quality

Improved surface finish and impact

Dosage Reference

Both grades deliver identical results. Select based on your application's density requirements. AmpliFill 300 is used at half the dosage of AmpliFill 150.

AmpliFill 150

For low-pressure applications (sewerage, conduits, profiles)

Lower cost option when density standards are flexible

Example: 25% CaCO3 filler

25 ÷ 5 = 5% AmpliFill 150

AmpliFill 300

For density-critical applications (pressure pipes, moulding)

Half the dosage - for strict density standards compliance

Example: 30% CaCO3 filler

30 ÷ 10 = 3% AmpliFill 300

Filler Increase Range

20-50% increase possible, adjusted based on your end product requirements

Packaging

Available in 25Kg Bags

Pro Tips for Best Results

Do: Pre-mix with Filler

For best results, pre-mix AmpliFill with your calcium carbonate before adding to the main compound.

Do: Start Conservative

Begin with the lower end of the dosage range and increase gradually to find your optimal loading.

Don't: Skip the Mixing Step

Ensure thorough mixing to achieve uniform distribution throughout your compound.

Don't: Exceed Recommended Dosage

More isn't always better. Stick to recommended dosages for optimal cost-effectiveness.