Engineered for the PVC industry. AmpliFill™ enables manufacturers to break through performance walls, reduce formulation costs, and maintain critical physical properties.

Maximize Filler.Minimize Cost.Maintain Strength.

The breakthrough technology that lets you increase filler loading by 20-50%* while improving product quality. Stop burning money in your extruder.

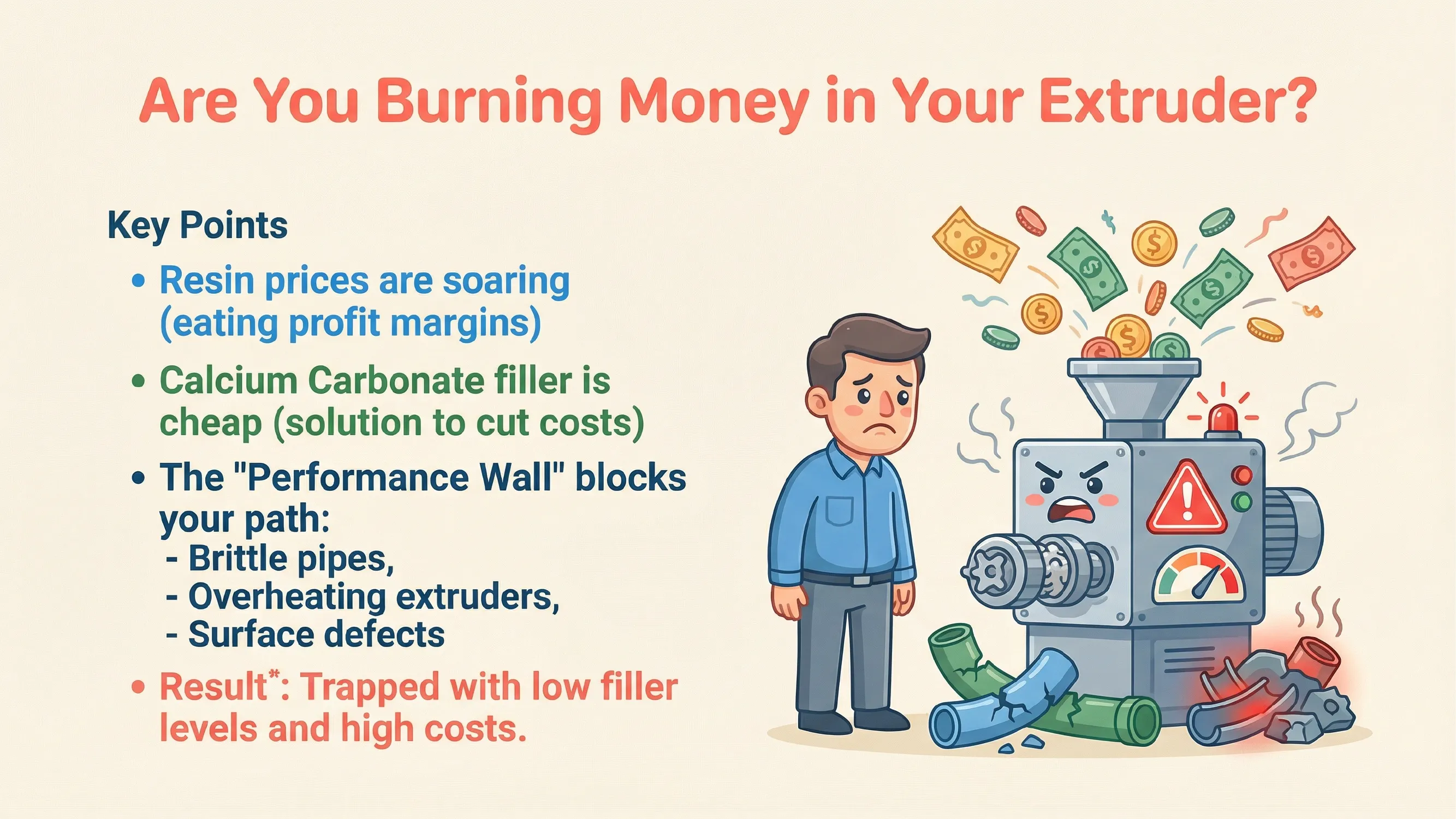

You're Burning Money

in Your Extruder

Every PVC manufacturer faces the same frustrating tradeoff: add more filler to save money, but sacrifice quality. Until now.

Brittle Pipes

High filler loading = weak products. Your quality suffers and customers complain.

Overheating Extruders

Friction builds up. Machines strain. Downtime increases. Profits disappear.

Surface Defects

Rough finish, fish eyes, poor appearance. Rejected batches pile up.

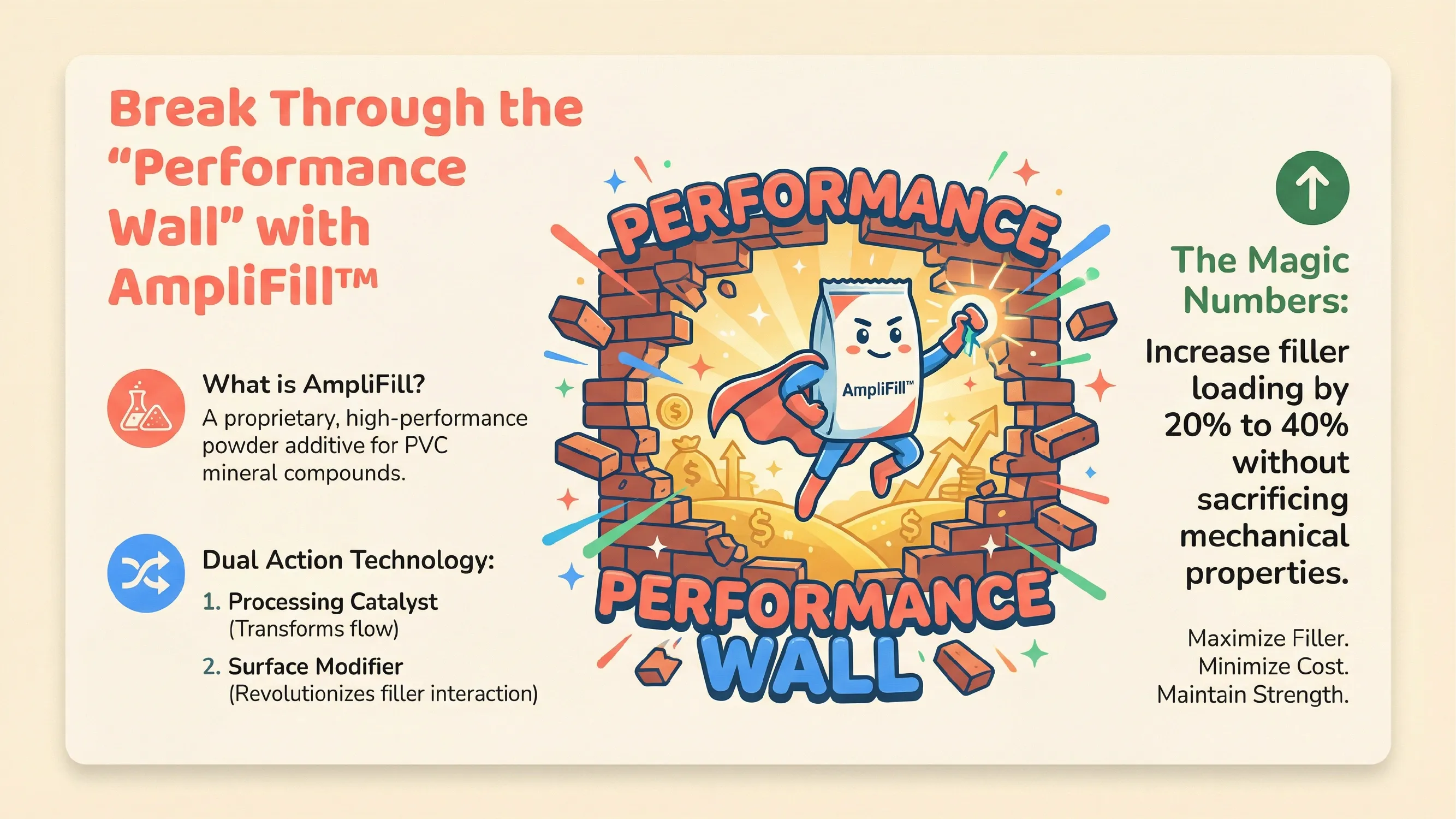

Break Through The Wall

AmpliFill transforms your filler into a high-performance additive. More filler, better quality, bigger profits.

Replace Expensive Resin

Swap costly resin with cheap filler while maintaining strength

Higher Throughput

Run your extruder faster with reduced friction and heat

Extended Equipment Life

Less friction means less wear on screws and barrels

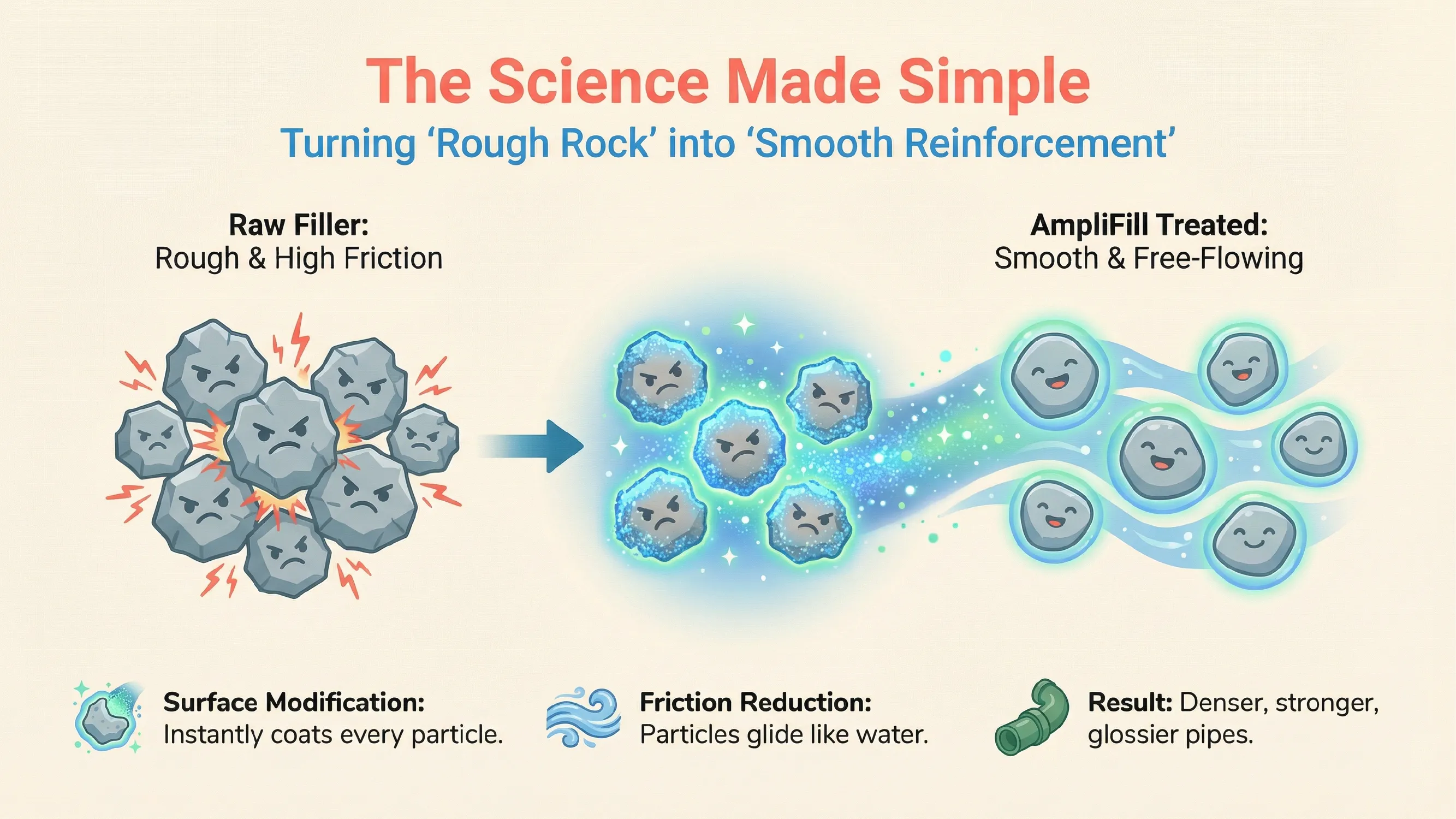

From 'Rough Rock'

to 'Smooth Reinforcement'

AmpliFill's dual-action technology transforms raw mineral filler into a high-performance additive that flows like water and bonds like steel.

Surface Modification

AmpliFill instantly coats every filler particle, creating a smooth, hydrophobic surface that eliminates moisture issues and improves dispersion.

Processing Catalyst

The treated particles glide through your extruder with dramatically reduced friction, lowering temperatures and enabling faster line speeds.

Turn Up Your Filler Level

Think of AmpliFill as the key that unlocks your filler dial. Increase quality and filler loadings.

Got Questions? We've Got Answers

Everything you need to know about AmpliFill, from dosage recommendations to ordering process.

Still have questions? We're here to help!